Definition of the term (“What does validation mean?”)

Validation plays a special role in all regulations of the GxP environment. Fundamentally, the validation means providing a documented proof that a certain process continuously produces a product that fulfills the previously defined specifications and quality characteristics. This is done to prevent any risk for human beings arising from the production process of quality assurance process. This especially affects the medical technology and the pharmaceutical industry.

What does software validation mean?

In this context, the GMP guidelines specify that the computer systems or software supporting the development or production of products of the above mentioned industries must also be validated. The software must be able to access the desired results exactly, continuously and reproducibly at all times. The FDA mentions the validation of software as a confirmation resulting from checks and the provision of objective evidence that the software specification complies with user requirements and the intended use and that the requirements are consistently met.

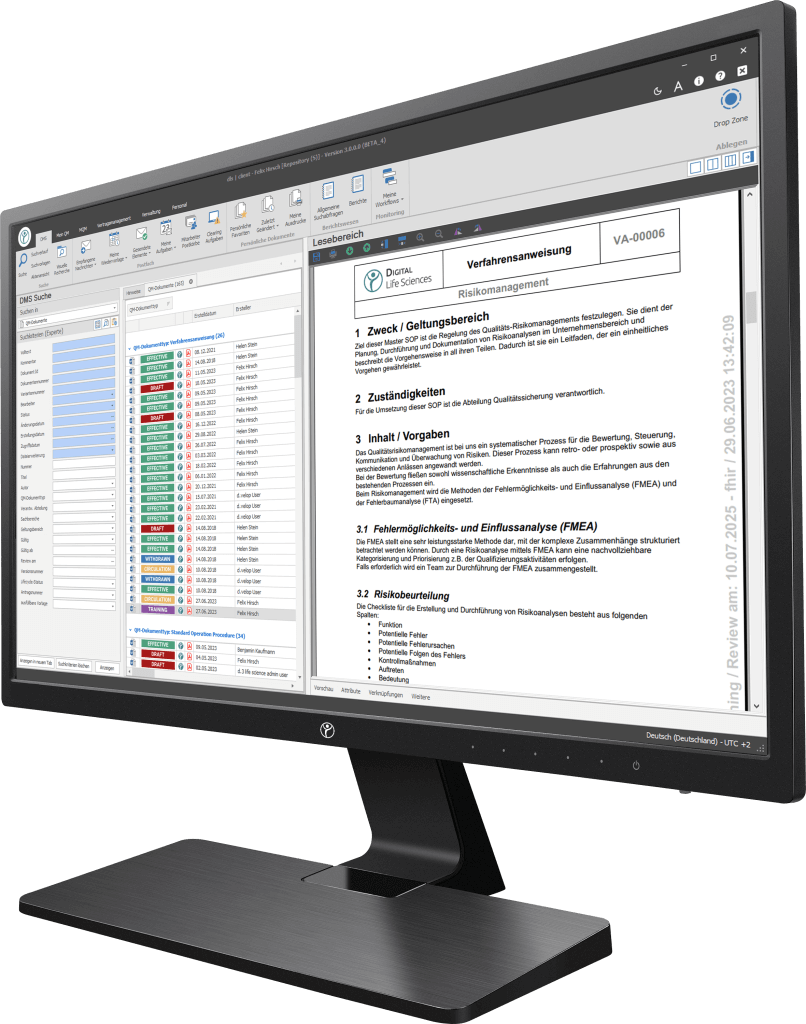

Your path to digitization — Discover our software

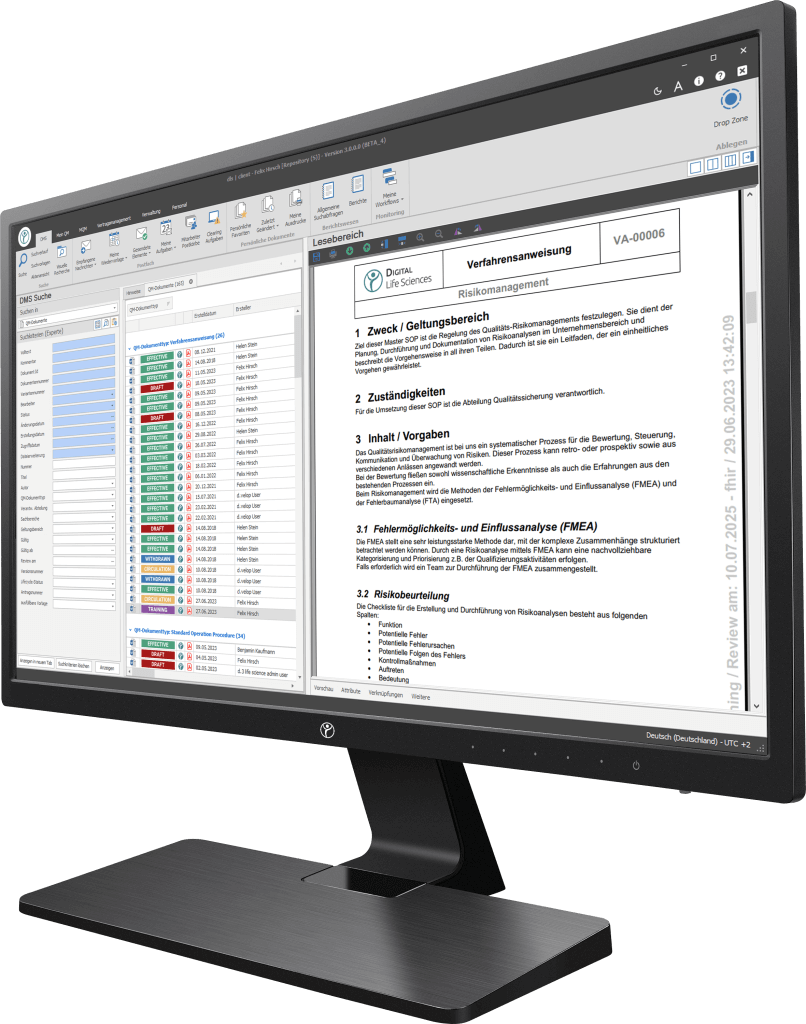

Our digitalization solutions primarily address document-based processes in manufacturing, production and quality management. The basis of the dls | eQMS is a holistic ECM/DMS system. The ECM/DMS system can be linked to your existing ERP system (e.g. SAP), thus enabling you to implement almost all document-based processes in your company.

What does medical validation mean?

Medical validation describes the determination of the validity of the test results in relation to the research question and represents the release of a laboratory finding to the contracting entity by a specialist.

Why is validation important?

The validation should respond to the questions, if the software is adequate for the intended use, if it provides the required functions, and if it is sufficiently reliable and efficient. Computer-based systems play a central role when producing and validating pharmaceutical or medicinal products. This explains why the systems must be validated from a GMP point of view.

In addition, validation provides documented proof that it is possible to create reproducibility. In other words, a company is capable of producing the same end product under the same conditions.

What is the difference between a user requirement specification and a functional specification?

The specifications describe in concrete terms how the contractor intends to meet the contracting entity’s requirements. However, the entire claim is first described as precisely as possible by the contracting entity in the user requirement specification.

Advantages of validations?

- Increasing the understanding and traceability of processes (systems, data, change management, …)

- Increased user confidence in the computer-based system

- Increased care in handling data and documents

- Increase of data security by means of controlled systems

- Increase of work efficiency by means of tested and secured processes

What role does risk management play in this?

Risk management is an important basis of quality management which should also be applied to the validation in the various forms and phases. This results in numerous quality-relevant and comprehensible decisions, which must also be documented and proven and which are included in the validation approach.

What application examples are there for validation?

Pharmaceutical industry:

- Process validation: Ensuring that production processes consistently produce medicine that is safe and effective.

- Cleaning validation: Verification that cleaning processes in production effectively remove residues and impurities.

Medical technology:

- Device validation: Validation of medical devices to ensure that they function reliably and deliver accurate results.

- Sterilisation validation: Confirmation that sterilisation processes are effective and that there is no microbial contamination.

Software development:

- System validation: Verification that a software system meets the specified requirements and is suitable for the intended use.

- User test: Validation that the software meets the expectations and needs of the end users.

Food industry:

- HACCP validation: Ensuring that Hazard Analysis and Critical Control Points (HACCP) plans are effectively implemented to ensure food safety.

- Packaging validation: Verification that packaging guarantees the freshness and safety of food throughout its shelf life.

Conclusion

Validation is an essential process for ensuring the quality, safety, and efficiency of products and systems in regulated sectors such as the pharmaceutical and medical technology industries. Validation proves that all processes and systems comply with the defined specifications and regulatory requirements. This not only protects end users, but also strengthens confidence in the products and increases operational efficiency. Thanks to continuous review and optimisation, the validated processes remain stable and reliable, which leads to better long-term results and higher customer satisfaction.

Start your digital transformation with our powerful, modular software solutions

Your path to digitization — Discover our software

Our digitalization solutions primarily address document-based processes in manufacturing, production and quality management. The basis of the dls | eQMS is a holistic ECM/DMS system. The ECM/DMS system can be linked to your existing ERP system (e.g. SAP), thus enabling you to implement almost all document-based processes in your company.

Frequently Asked Questions (FAQs)

What is the difference between verification and validation?

- Verification checks whether a product or system meets the defined specifications. Validation ensures that the product or system meets the needs and requirements of the end user.

What does validation mean? (What is validation?)

- Validation ensures that a product or system continuously meets the defined specifications and quality features. It proves the reliability and reproducibility of processes or systems in meeting the expectations of end users. This is of particular importance in regulated industries, especially in the pharmaceutical and medical technology sectors, where compliance with strict regulations is crucial for product success and patient safety.

Validation Explanation: Why is it so important in regulated industries?

- Validation is crucial to ensure compliance with legal requirements. It ensures that products and processes are safe, effective and of high quality. Proper validation strengthens confidence in the manufactured products and minimizes the risk of errors.

What are the basic steps in a validation process?

The validation process comprises several important steps:

- Planning: Definition of requirements and implementation of a risk analysis.

- Implementation: Testing and documenting the results.

- Review of the results: Ensure that all requirements are met.

- Continuous monitoring: Regular review and optimization of the process.

These steps are crucial to ensure the quality and safety of a product or system in the long term.

How does process validation differ from method validation?

- Process validation checks whether a production process reliably delivers the expected results. Method validation ensures that a test method provides the desired measurements reliably and precisely.

What is prospective validation?

- Prospective validation is carried out prior to the routinised application of a new process. It includes tests and documentation under controlled conditions to ensure that the process meets the specified requirements.