Definition of the term ("What are preventive actions?")

In ISO 9000, a preventive action is described as an “action to eliminate the cause of a possible error or other possible undesirable situation”. In this respect, the primary aim is to identify and prevent the causes of errors before they occur and to ensure that errors therefore do not occur .

What is required within preventive actions?

ISO 9001 requires preventive actions to eliminate possible causes of errors in order to prevent their occurrence. Furthermore, it is required that the resulting actions are adapted to the size of the possible error. In addition to that, a clear and documented procedure is required, which includes the following:

• Searching for possible errors and the reasons for them

• Evaluation of the necessity of the action to avoid the potential error occurrence

• Research and realization of necessary measures

• Documentation on the results of the action taken

• Evaluation of the effectiveness of the action taken

What are the benefits of preventive actions?

On the one hand, this approach enables the quality of the products to be kept at a consistently high level and, on the other hand, it saves considerable costs that a possible error would cause .

When are preventive actions applied and required?

Corrective And Preventive Action (CAPA) are among the mandatory components of GMP-compliant work (QMS). They are also considered to be one of the critical subject areas during inspections. Since the introduction of QMS, it has manifested itself as the element of a QMS that presents the greatest hurdles in terms of understanding, adoption, and company-wide implementation .

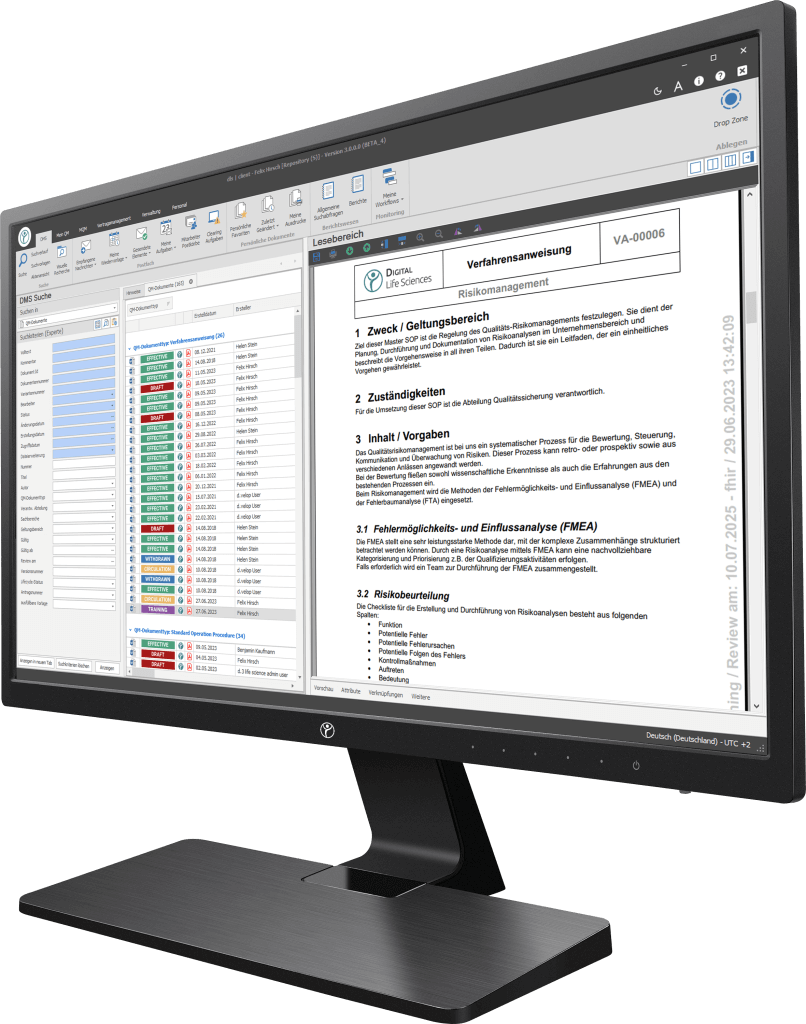

Your path to digitization - Discover our software

Our digitization solutions primarily address document-based processes in manufacturing, production and quality management. The basis of the dls | eQMS is a holistic ECM/DMS system. The ECM/DMS system can be connected to your existing ERP system (e.g. SAP) and, thus, map almost all document-based processes in the company.

Steps to implement corrective actions

The implementation of preventive actions requires a structured approach. Here are some steps you can follow:

- Risk evaluation: Identify potential risks and hazards in your process or product. This can be done through analysis, audits and observations.

- Measure plan: Develop a clear plan to minimize or eliminate these risks. This may include updating procedures, training employees, or improving processes.

- Implementation: Put your action plan into practice and ensure that all relevant employees are trained and informed.

- Monitoring and measurement: Track the results of your preventive actions and check regularly to see if they are effective. Adjust the plan if necessary.

- Continuous improvement: Use the collected data and findings to make continuous improvements and optimize your quality management system.

What is the difference between corrective and preventive actions?

There are generally two different procedures for avoiding errors. One procedure is the corrective action and the other is the preventive action.

If an error or deviation has already been detected, the further procedure is described in the form of an error analysis and corrective action. However, if no error/deviation has been detected yet, but a possible source of error has been identified in advance, then subsequent processes are declared as a preventive action.

Conclusion

Implementing preventive actions in accordance with ISO 9001 can bring considerable benefits to your company. They do not only help prevent quality problems, but also contribute to increased customer satisfaction and cost efficiency. A proactive approach to quality assurance is critical to succeeding in today’s competitive business environment.

Start your digital transformation with our powerful, modular software solutions

Frequently Asked Questions (FAQs)

What is ISO 9001?

ISO 9001 is an international standard for quality management systems that aims to increase customer satisfaction and improve a company’s efficiency.

Why are preventive actions important?

Preventive actions are important to avoid potential quality problems, reduce costs, and increase customer confidence.

How do I identify potential risks in my company?

Potential risks can be identified through analyses, audits and observations.

What steps are required to implement preventive actions?

The steps for implementing preventive actions include risk evaluation, action plan, implementation, monitoring and measurement, and continuous improvement.

What are the benefits of implementing preventive actions?

Implementing preventive actions can lead to the prevention of quality problems, cost savings, and increased customer satisfaction.