Definition of the term ("What is a corrective action?")

In ISO 9000, a corrective action is described as “action taken to eliminate the cause of a detected error or other undesirable situation”. In this respect, it is less a question of rectifying the error, e.g. by means of correction, but rather of recognizing and eliminating the causes of errors so that identical errors do not occur again.

What is required within corrective actions?

ISO 9001 requires corrective actions to eliminate causes of errors with regard to a repeated occurrence. Furthermore, it is required that the resulting actions are adapted to the size of the error that has occurred. In addition to that, a clear documented procedure is required, which includes the following:

a) Error evaluation (including customer complaints),

b) Identifying the causes of errors,

c) Evaluation of the need for action to prevent the recurrence of errors,

d) Determination of necessary actions and their realization,

e) Documentation of the results of the actions taken, and

(f) Evaluation of the effectiveness of corrective actions taken.

What are the benefits of corrective action?

Implementing corrective actions according to ISO 9001 offers several benefits for your company. First, it helps to identify and correct quality issues early, before they become major problems. Second, it contributes to continuous improvement by enabling learning from errors and optimizing processes.

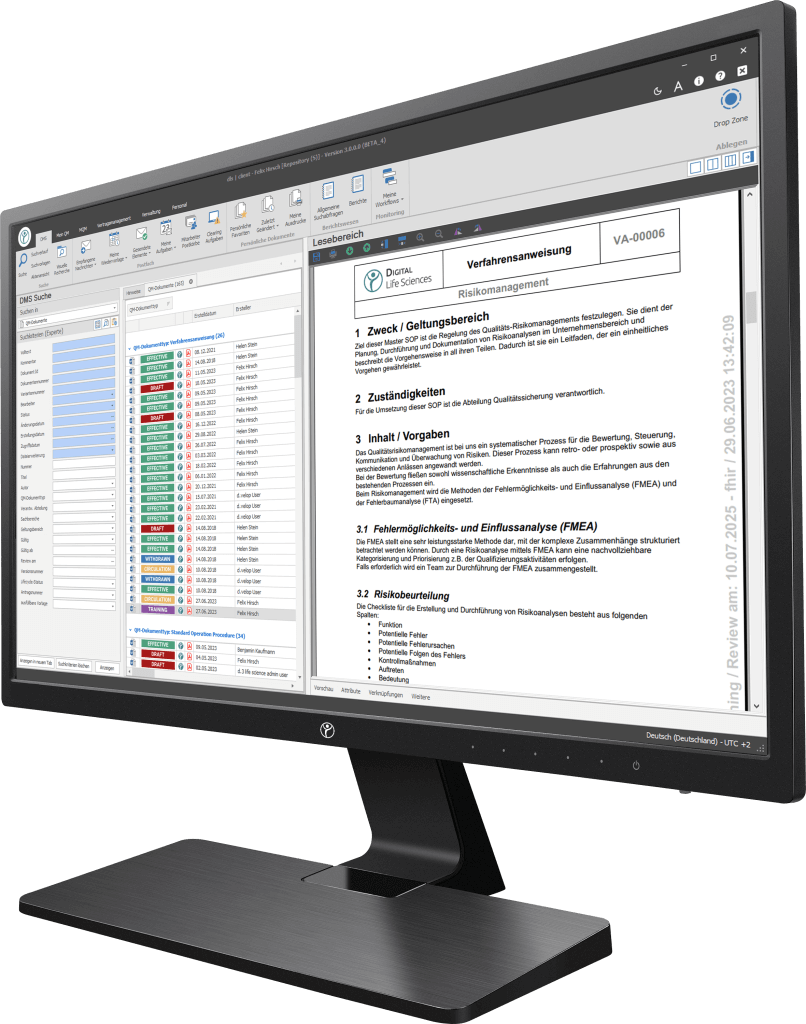

Your path to digitization - Discover our software

Our digitization solutions primarily address document-based processes in manufacturing, production and quality management. The basis of the dls | eQMS is a holistic ECM/DMS system. The ECM/DMS system can be connected to your existing ERP system (e.g. SAP) and thus map almost all document-based processes in the company.

Steps to implement corrective actions

- Identification of the problem: The first step of implementing corrective actions is to identify the problem. This can be done through internal audits, customer feedback, or other quality control procedures.

- Root cause analysis: After the problem has been identified, it is important to analyze the causes. This helps to ensure that the problem does not reoccur.

- Measure planning: Based on the root cause analysis, an measure plan should be created. This plan should clearly define what steps will be taken to address the problem.

- Implementation of measures: The next step is the implementation of the planned measures. This may include training, process changes, or other activities.

- Monitoring and review: Once the actions have been implemented, it is important to monitor progress and ensure that the problem has actually been solved.

- Documentation: All steps in the corrective action process should be carefully documented to facilitate tracking and reviewing.

What is the difference between corrective and preventive actions?

There are generally two different procedures for avoiding errors. One procedure is the corrective action and the other one is the preventive action.

If an error or deviation has already been detected, the further procedure is described in the form of an error analysis and corrective action. However, if no error/deviation has been detected yet, but a possible source of error has been identified in advance, then subsequent processes are declared as a preventive action.

Conclusion

The implementation of corrective actions in accordance with ISO 9001 is crucial for maintaining high quality standards in your company. By identifying and addressing quality issues, you can build customer confidence and ensure long-term success. Remember that careful planning and documentation are critical to the success of this process.

Start your digital transformation with our powerful, modular software solutions

Frequently Asked Questions (FAQs)

What is the purpose of corrective actions according to ISO 9001?

Corrective actions are used to identify and correct quality problems to ensure compliance with quality standards.

What are the benefits of implementing corrective actions?

The implementation of corrective actions enables the early detection and elimination of quality problems as well as the continuous improvement of processes.

How should corrective actions be documented?

Corrective actions should be carefully documented, including the identification of the problem, root cause analysis, action plan, and implementation steps. The easiest way to achieve this is with appropriate QM software solutions.

How often should internal audits be conducted to identify quality issues?

Internal audits should be conducted regularly to identify quality issues early. Frequency may vary depending on business needs.

What role does ISO 9001 play in corrective actions?

ISO 9001 sets the standards for quality management and provides guidelines for implementing corrective actions in accordance with international best practices.