Definition of the term ("What is GxP?")

GxP, short for “Good Practices,” is a collective term that encompasses various regulations, standards and guidelines that control the quality and compliance of products and processes in the life sciences industry. These practices are critical to the safety and effectiveness of medicinal products, medical devices and other related products.

What do the GxP abbreviations stand for?

Before we dive deeper, let’s take a look at the most important abbreviations in the GxP context:

- GMP – Good Manufacturing Practices: GMP regulates the manufacturing and quality control of medicinal products and medical devices and emphasizes consistency and product safety.

- GCP – Good Clinical Practices: GCP sets the ethical and scientific standards for executing clinical trials and ensures the welfare of participants and the reliability of study data.

- GLP – Good Laboratory Practices: GLP regulates the execution of non-clinical laboratory studies and guarantees the accuracy and reliability of test data.

- GDP – Good Distribution Practices: GDP controls the distribution of medicinal products and ensures their quality during transport and storage.

Why is GxP important?

The life sciences industry is inherently complex and sensitive. A single quality or compliance error can have serious consequences that can compromise patient safety and damage an organization’s reputation. Here’s why GxP is essential:

- Patient safety: The primary focus of GxP is to protect patients. Stringent quality control measures ensure that products reaching consumers are safe, effective and free of impurities or defects.

- Regulatory compliance: Compliance with GxP standards is mandatory in many countries. Companies must comply with these regulations in order to obtain approval for their products and operate legally.

- Reputation and trust: A company’s reputation is its most valuable asset. GxP compliance promotes the trust of stakeholders, including healthcare providers, regulators and patients.

Your path to digitization - Discover our software

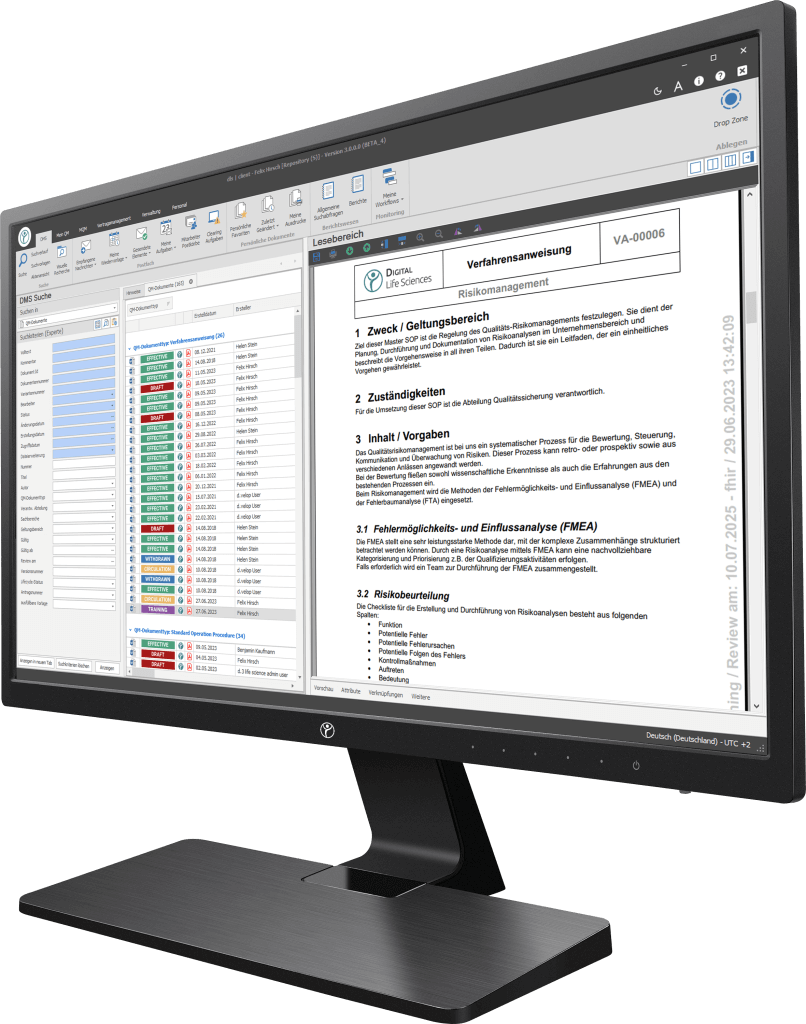

Our digitization solutions primarily address document-based processes in manufacturing, production and quality management. The basis of the dls | eQMS is a holistic ECM/DMS system. The ECM/DMS system can be connected to your existing ERP system (e.g. SAP) and thus map almost all document-based processes in the company.

Important principles of GxP

To maintain quality and compliance, the GxP principles are structured around the following key concepts:

- Documentation: Comprehensive and well-maintained documentation is the foundation of GxP. Records of manufacturing processes, clinical studies and laboratory tests ensure transparency and traceability. The best way to achieve this is with appropriate QM software solutions .

- Training and competence: Ensuring that staff are properly trained and competent is critical. GxP requires ongoing training to keep employees updated on the industry’s best practices.

- Risk management: Identifying and minimizing risks is critical. Companies need to conduct risk evaluations to anticipate potential problems and take preventive action.

- Continuous improvement: GxP promotes a culture of continuous improvement. Regular audits and evaluations help companies to identify sections for improvement.

The role of technology in GxP

In today’s digital era, technology plays a critical role in GxP compliance. Electronic documentation, automated quality control systems and data analytics contribute to efficiency and accuracy.

Conclusion

GxP is the backbone of the life sciences industry, ensuring that products are safe, effective and in compliance with regulations. Companies that adopt the principles of GxP do not only protect the well-being of patients, but also strengthen their reputation and trustworthiness in the competitive marketplace.

Start your digital transformation with our powerful, modular software solutions

Frequently Asked Questions (FAQs)

To which industries does GxP apply?

GxP applies primarily to the pharmaceutical industry, medical devices, biotechnology and other sections within the life sciences industry.

How can companies keep up to date with changing GxP regulations?

Companies can stay informed by regularly monitoring websites of regulatory authorities, attending industry conferences and working with compliance experts.

What are the consequences of non-compliance with GxP regulations?

Non-compliance can result in product recalls, legal penalties, reputational damage and, in extreme cases, loss of market access.

Is GxP compliance a global requirement?

Although the GxP principles are recognized worldwide, specific regulations may differ from country to country.

Can small companies in the life sciences industry afford GxP compliance?

Yes, many regulators offer resources and guidelines tailored to the needs and size of businesses.