Definition of the term ("What is a Performance Qualification?")

In the world of pharmaceutical manufacturing and quality assurance, performance qualification (PQ) is a critical step in ensuring that equipment and systems used as part of quality assurance, particularly in the GMP-compliant industrial manufacture of regulatory controlled products (e.g., pharmaceuticals), function properly in the production environment and meet specified requirements. The performance qualification (PQ) is a critical part of the validation process in the pharmaceutical industry and is also the final phase of equipment qualification, following the installation qualification (IQ) and operation qualification (OQ).

The significance of PQ

The PQ has a crucial significance as it ensures that all pharmaceutical processes are stable and reliable. Any error or failure at this stage can have serious consequences for the product quality.

The phases of performance qualification

The PQ consists of several phases that must be carried out systematically to ensure the proper functioning of equipment and systems.

- Preparation: In this phase, all necessary documentation is created, including test plans and protocols. It is important to ensure that all requirements and specifications are clearly defined.

- Execution of tests: The actual tests are performed according to the prepared plans. During this process, all aspects of the device function are tested to ensure that they meet the requirements.

- Documentation of results: All test results are documented in detail. This is critical for compliance and allows deviations or problems to be identified and resolved.

- Analysis and approval: The collected data and results are analyzed and an approval or rejection of the equipment qualification is made.

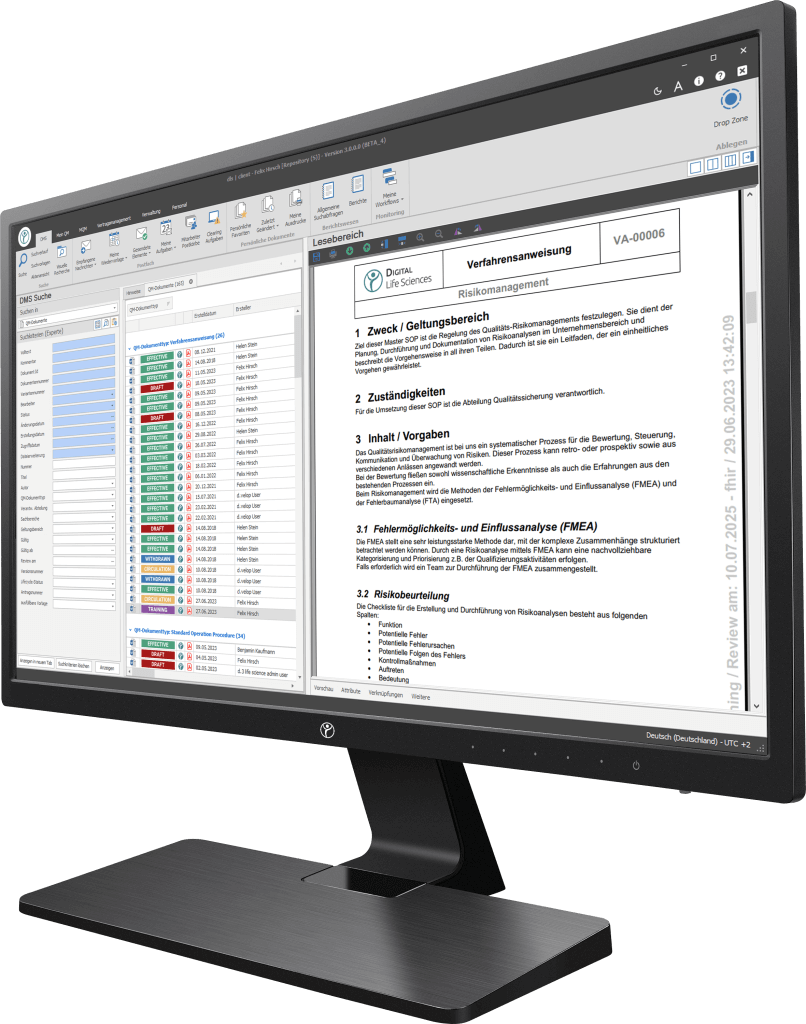

Your path to digitization - Discover our software

Our digitization solutions primarily address document-based processes in manufacturing, production and quality management. The basis of the dls | eQMS is a holistic ECM/DMS system. The ECM/DMS system can be connected to your existing ERP system (e.g. SAP) and, thus, map almost all document-based processes in the company.

Best practices for a successful PQ

A successful PQ requires careful planning and execution. Here are some best practices to keep in mind:

- Clear documentation: Ensure that all documentation, including test logs and reports, is accurate and complete.

- Employee Training: Employees performing the tests should be well trained to ensure accurate and reliable results.

- Risk evaluation: Conduct a thorough risk evaluation prior to the PQ to identify potential issues in advance.

- Validated test methods: Use validated test methods that comply with current industry standards.

Conclusion

The performance qualification (PQ) is a critical step in the qualification of pharmaceutical plants. It ensures that all equipment and systems function properly and do not compromise product quality. Careful planning, execution and documentation are essential for the success of the PQ.

Start your digital transformation with our powerful, modular software solutions

Frequently Asked Questions (FAQs)

Why is the Performance Qualification (PQ) so important in pharmaceutical production?

The PQ is important because it ensures that all equipment and systems are functioning properly, which ensures product quality and patient safety.

What are the phases of the PQ?

The PQ includes the phases of preparation, execution of tests, documentation of results, and analysis as well as approval.

What happens if the PQ fails?

If the PQ fails, the reasons must be identified and corrected before the plants and systems can be put into operation.

How often must a PQ be performed?

The PQ must be performed each time new equipment is installed or significant changes are made to existing equipment.

What is the role of PQ in regulatory compliance?

The PQ is critical for compliance with regulations and standards in the pharmaceutical industry as it ensures that plants are functioning properly. Regulations in this regard are, for example:

- EC GMP Guideline, Chap. 3 and Annex 15 and AMWHV § 5

- ISO 17025

- For plant-specific, detailed requirements: EDQM Quality Management Guidelines

- General requirements of pharmacopoeias

- USP General Chapter <1058> “Analytical Instrument Qualification”

- Standards (EN, ISO, DIN)