Definition of the term ("What is the installation qualification?")

The installation qualification, also known as IQ, is a process of verifying that all solutions, equipment and plants in a production facility have been installed according to the manufacturer’s specifications. This process ensures proper placement and connection of equipment and systems to ensure proper operation. In addition, it is ensured that the products/attachments/solutions are tailored to the user’s requirements and therefore meet the specifications(specifications or Functional Specification) have been created and sufficient documentation exists as proof of this.

Why is installation qualification important?

The significance of the installation qualification in the pharmaceutical industry cannot be overstated. Here are some reasons why it is indispensable:

- Ensuring product quality: The IQ ensures that all solutions, equipment and plants are functioning properly, ensuring the quality and purity of the pharmaceutical products produced.

- Regulatory compliance: Pharmaceutical companies must comply with strict regulatory standards. The IQ is a critical step in demonstrating compliance with these regulations.

- Avoiding downtime: Incorrect installation of solutions or plants can result in costly downtime. The IQ minimizes this risk by making sure everything is working properly.

- Cost efficiency: By identifying problems early and ensuring a smooth installation, companies can save costs in the long term.

The installation qualification process

The IQ consists of several steps that must be performed carefully:

- Step 1: Planning: This step defines the requirements for the IQ, including the solutions, equipment and plants to be qualified.

- Step 2: Carrying out the qualification: The actual qualification is carried out paying particular attention to safety-relevant and process-critical aspects.

- Step 3: Documentation: All qualification results are carefully documented to prove compliance with the standards.

- Step 4: Reporting: A comprehensive final report will be prepared that includes all tests and results performed.

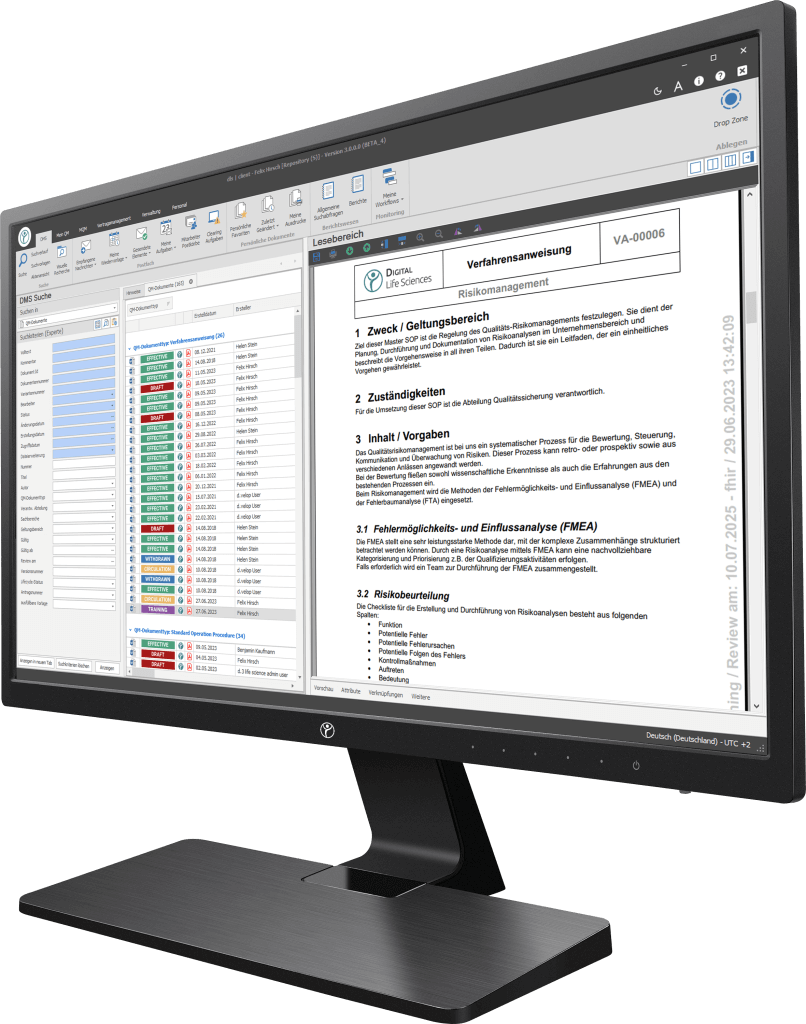

Your path to digitization - Discover our software

Our digitization solutions primarily address document-based processes in manufacturing, production and quality management. The basis of the dls | eQMS is a holistic ECM/DMS system. The ECM/DMS system can be connected to your existing ERP system (e.g. SAP) and, thus, map almost all document-based processes in the company.

Installation qualification challenges

While the IQ is of critical significance, it also presents challenges:

- Complexity: Qualification can be complex, especially in large production plants with many devices and systems.

- Time constraints: Performing the IQ can take time, which can affect overall production time.

Conclusion

The installation qualification is an indispensable step in the pharmaceutical industry to ensure the efficiency and safety of solutions, equipment and plants. It contributes to product quality, ensures compliance and minimizes downtime. Despite the challenges, the IQ is a cornerstone of any pharmaceutical manufacturing plant.

Start your digital transformation with our powerful, modular software solutions

Frequently Asked Questions (FAQs)

What is the main purpose of the installation qualification?

The main purposes of the installation qualification are to ensure product quality, compliance with regulatory requirements, prevention of downtime, and cost efficiency.

Which industries need installation qualification?

Installation qualification is widely used in industries such as pharmaceutics, biotechnology and food manufacturing.

Are there alternatives to the installation qualification?

The installation qualification is a standard procedure widely used in the pharmaceutical industry. There are no widely spread alternatives to ensure the same safety and quality.

What role does documentation play in the installation qualification?

Documentation is critical to prove that qualification has been properly performed and to ensure that all required steps have been completed.

How long does the installation qualification process usually take?

The duration of the process depends on the size and complexity of the production plant. It can last from weeks to several months.