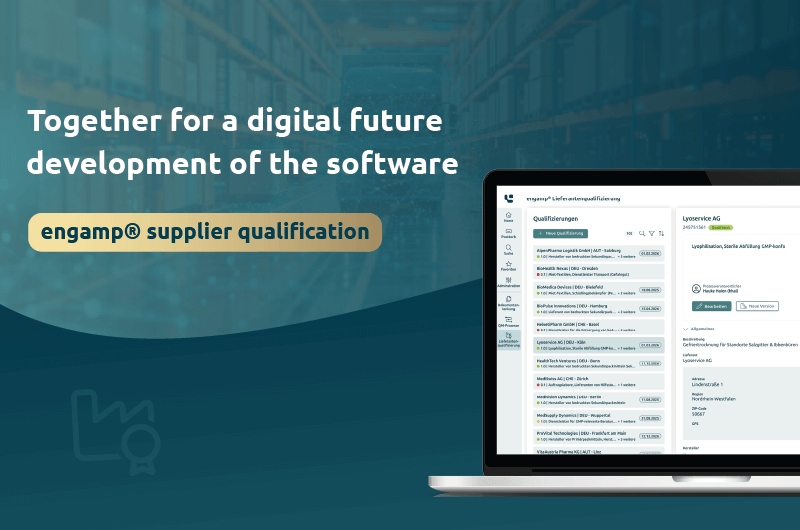

Together for a digital future — development of the software engamp® supplier qualification

In times of global supply chains and increasing out-sourcing, supplier qualification presents companies with considerable administrative challenges. In the life sciences sector in particular, this process is not only time-consuming but also cost-intensive in order to ensure that services are only procured from qualified suppliers.

To make this process more efficient, Digital Life Sciences GmbH, in cooperation with our long-standing partners MEDICE Arzneimittel Pütter GmbH & Co. KG and Rottendorf Pharma GmbH, has developed the software solution engamp® supplier qualification. Both companies are actively involved in the development process as pilot customers and are helping to create a solution that is optimally tailored to the requirements of the industry.

In this blog post, we shed light on the increasing importance of supplier qualification in the digital age and provide deeper insights into the development process of the software solution.

Why supplier qualification is indispensable in the pharmaceutical industry

Quality assurance starts with the supplier — the crucial factors for the pharmaceutical industry

Supplier qualification is a fundamental component of quality management. It ensures that the auxiliary and active ingredients used are sourced from qualified partners who meet both legal and internal quality requirements. It guarantees the stability of essential supply chains and production processes.

Shortcomings in qualification can have serious consequences, including product defects, violations of regulatory requirements and increased risks to patient safety.

Supplier qualification therefore involves much more than simply filling out questionnaires or ticking off checklists. It creates the basis for trust, reliability, and legal certainty (compliance) in an increasingly fast-moving world.

The three core aspects of supplier qualification:

- Regulatory compliance: Compliance with GMP guidelines (Good Manufacturing Practice), ISO standards, and other regulations.

- Quality assurance: Guarantee of consistent product quality.

- Risk management: Identification and minimisation of potential risks from non-compliant suppliers.

Factors such as cost pressure and globalisation are leading to a situation in which active ingredients and additives are increasingly no longer being produced in-house and processes are being outsourced. However, responsibility for quality remains with the pharmaceutical manufacturer, who must ensure that their suppliers maintain the same high quality standards.

The German Ordinance for the Manufacture of Medicinal Products and Active Pharmaceutical Ingredients specifically obliges the manufacturer to ensure the qualification of suppliers […] im Rahmen des QM-Systems […] in accordance with a written or electronic procedure. Similar phrases can also be found in the GMP guidelines and other regulations.

Why companies need to qualify their suppliers

The quality management system of a pharmaceutical manufacturer ensures that products are continuously manufactured to a high level of quality and that patients are not exposed to any risks due to inadequate safety, quality or efficacy (EU GMP guidelines, chapter 1).

In order to guarantee these standards, companies have a comprehensively planned pharmaceutical quality system that covers all areas and is fully documented.

However, the processes at suppliers who deliver materials such as auxiliary ingredients and active ingredients or provide GxP services are not always subject to direct control. Therefore, documented processes must be used to ensure that the supplier has the necessary approvals and complies with the regulations of appropriate good manufacturing practice.

The qualification of suppliers has a direct impact on product quality and is becoming increasingly important in the context of global supply chains. However, many companies still rely on paper-based procedures for qualification, which is often time-consuming and error-prone.

This is precisely where the pilot project with MEDICE and Rottendorf comes in – to illustrate how important it is to drive the digital transformation forward.

Working together for greater efficiency — the cooperation with MEDICE & Rottendorf Pharma

Digital Life Sciences’ electronic quality management system (eQMS) has been supporting companies such as MEDICE and Rottendorf with GxP-compliant documentation for years. The control of specification and verification documents, the planning and tracking of training courses as well as the documentation of quality management processes contribute to compliance with the quality standard.

The qualification of suppliers is also becoming increasingly important for inspections. In view of increasing requirements, the wish was expressed at the end of 2023 to also digitally document the supplier qualification process. At this time, Digital Life Sciences already had concrete plans to transfer the tried and tested functions of the eQMS into a newly designed web application. Agreements were made to implement the supplier qualification module as one of the first in this new environment.

The companies behind the pilot project

MEDICE Arzneimittel Pütter GmbH & Co. KG

MEDICE Arzneimittel Pütter GmbH & Co. KG is a manufacturer of medicinal products and medical devices. Founded in Iserlohn, Germany in 1949, the company is still family-run today and covers areas of expertise such as pharmacy, digital health and nutrition concepts. MEDICE was a pilot customer for the eQMS of the former d.velop Life Sciences in 2007 and was significantly involved in the development of the software modules.

Rottendorf Pharma GmbH

Rottendorf Pharma GmbH, located around 80 km further north in Ennigerloh, is one of the leading contract manufacturers and developers of solid oral dosage forms. Since its foundation in 1928, the company has been active in the production, packaging, and development of formulations and analytical processes for the international pharmaceutical industry. Rottendorf has been using the electronic QMS by Digital Life Sciences since 2017.

Digital Life Sciences GmbH

Digital Life Sciences GmbH was founded in April 2007 and is a provider of digital and GxP-compliant documentation solutions with a focus on the requirements of the life sciences industry. The solutions are based on the ECM/DMS system of d.velop AG – d.velop documents (formerly d.3ecm) – and extend this platform with functions for contolled document management and quality management.

With many years of experience as a digitiser in the regulated environment, we offer our customers a comprehensive range of services, such as professional, validation and support services.

The pilot project — digitalisation as the key to efficient supplier qualification

After an extensive analysis of the processes at the beginning of 2023, contractual negotiations were concluded in the summer, so that the kick-off for software development could take place on September 7, 2023.

MEDICE and Rottendorf are actively involved in the development process as pilot customers. In addition to the initial development of a joint product vision with the key functions, the two development partners make valuable contributions to technical requirements through regular jour-fix meetings and provide feedback on the implementations to date.

MEDICE and Rottendorf have also used documented procedures to qualify their suppliers so far. However, without a digital process, it was time-consuming to keep the status of a supplier and all associated documents centrally available. The aim was therefore to map the supplier qualification process completely digitally and to precisely respond to the needs of the users.

More efficiency through digitalisation — three key functions of the new software

The main functionalities are divided into three central product objectives:

- Qualification & status:

- Creation of a “single point of truth” for the status of all suppliers

- Risk-based classification of suppliers

- Digital process for qualifying, approving, and locking suppliers

- Dossier of documents for the qualification

- Document checklist: Specification of a checklist for necessary documents based on risk evaluation

- Audit planning:

• Systematic planning of audit appointments

• Assignment of individual audit team members

• Management of all audit-relevant documents

• Creation of an annual audit plan

The development process — from the initial vision to implementation

A regular exchange with specialist users is a key quality feature in the development of the application. The process analyses are followed by the design of individual functions and their coordination with regard to solutions. Following these intensive discussions, developers work in a cross-functional team to implement relevant functions, after which the finished increment is presented.

This agile approach ensures that we can react quickly to change requests and make the functions user-friendly.

In the pharmaceutical industry, the applicable laws and guidelines provide a certain amount of leeway for implementation. It is therefore crucial to coordinate the various processes within this application. Reading the regulations as well as contact with inspectors and other specialist users provide valuable support here.

Future outlook — engamp® supplier qualification

In November 2024, the first executable version of engamp® supplier qualification was released and successfully installed on the test systems of our pilot customers. Since then, subsequent versions with additional functionalities have been released at short intervals.

Over the course of the year, not only will further product targets be realised, but the engamp® product line will also be expanded with additional modules that can be run independently of the Digital Life Science System.

The aim is to provide a solution that enables the supplier qualification process to not just be a supplement to the eQMS Digital Life Science. Instead, it will be available as an independent solution with its own document storage and document control.

You can find out more about our partnership in our news article “MEDICE and Rottendorf as pilot customers — software for supplier qualification“

Digitalisation of supplier qualification – a holistic solution for the pharmaceutical industry

The pilot project impressively illustrates how important it is to digitise the supplier qualification process – especially within a constantly growing industry that is facing ever new and more complex challenges. This includes the management of global supply chains and strict compliance with regulatory requirements.

Our close cooperation with the pilot customers MEDICE Arzneimittel Pütter GmbH & Co. KG and Rottendorf Pharma GmbH played a central role in this project. Together, we have developed engamp® supplier qualification software, a holistic solution that not only increases efficiency and transparency, but also acts as a central source of information. It ensures that all qualifications are carried out in accordance with GMP guidelines and ISO standards.

We would like to thank our development partners for their valuable and constructive cooperation! The use of the functions that have already been implemented provides us with important insights that will help us to continuously optimise the product as we achieve our other product goals over the course of 2025.

You can find more detailed information about our solution at: https://www.digital-ls.de/en/solutions/supplier-qualification/