Definition of the term ("What is the GAMP5?")

The GAMP5 is a set of guidelines and best practices developed by the International Society for Pharmaceutical Engineering (ISPE) to ensure the quality and compliance of automated systems in the pharmaceutical and healthcare industries. GAMP stands for “Good Automated Manufacturing Practice”. This is the fifth version of these guidelines, which takes into account the latest industry developments and regulatory changes.

Why is the GAMP5 important?

The pharmaceutical industry relies heavily on automated systems for various processes, including manufacturing, quality control and data management. Ensuring the reliability and integrity of these systems is crucial to prevent errors that could jeopardize the safety and effectiveness of products.

The GAMP5 addresses this need by deploying a structured framework for the validation and maintenance of automated systems. It not only helps to meet regulatory requirements, but also improves overall operational efficiency.

What are the principles of GAMP5?

GAMP5 is based on several key principles:

- Risk-based approach: A fundamental component of GAMP5 is the application of a risk-based approach. It recognises that not all systems are equally critical and focuses validation efforts where they are most needed. This approach ensures an efficient allocation of resources.

- Documentation and records: Proper documentation is at the heart of GAMP5. It requires thorough documentation of all aspects of the automated system, from design and development to testing and maintenance. This meticulous recording helps to prove compliance to supervisory authorities.

- Change control: Change is inevitable in any industry, and the pharmaceutical sector is no exception. GAMP5 emphasises the significance of effective change control procedures to ensure that modifications to automated systems do not compromise their integrity or compliance.

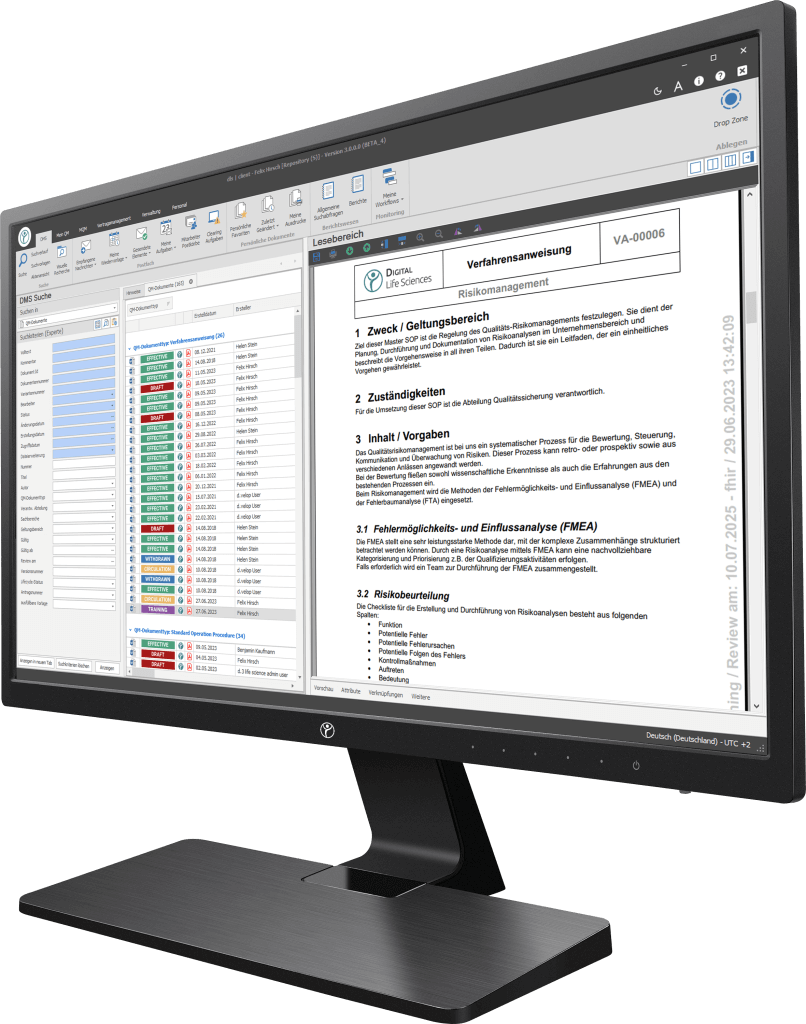

Your path to digitisation - Discover our software

Our digitisation solutions primarily address document-based processes in manufacturing, production and quality management. The basis of the dls | eQMS is a holistic ECM/DMS system. The ECM/DMS system can be connected to your existing ERP system (e.g. SAP) and thus map almost all document-based processes in the company.

How can the GAMP5 be implemented?

The implementation of GAMP5 in a pharmaceutical company comprises several steps:

- Risk evaluation: The process begins with a comprehensive risk evaluation to identify critical systems and potential threats. This evaluation informs the prioritisation of validation efforts.

- User requirement specification: Companies need to define clear and detailed user requirements for their automated systems. This document serves as the basis for system design and validation.

- System design and development: The automated system is designed and developed based on the user requirement specification. GAMP5 provides guidelines to ensure that the system fulfills its intended purpose.

- Installation and operational qualification (IQ/OQ): IQ/OQ tests verify that the system is installed correctly and operates according to its design specifications. This phase is crucial for system validation.

- Performance qualification (PQ): PQ tests confirm that the system works consistently within defined parameters and meets user requirements. A successful PQ is an important milestone in the validation process.

What are the advantages of GAMP5?

The implementation of GAMP5 offers numerous advantages for pharmaceutical companies:

- Regulatory Compliance: GAMP5 helps companies ensure compliance with industry regulations and guidelines and reduce the risk of costly regulatory issues and product recalls.

- Improved product quality: By ensuring the reliability of automated systems, GAMP5 contributes to the production of high-quality pharmaceutical products.

- Increase in efficiency: Efficiently validated systems lead to less downtime and operational interruptions, resulting in increased efficiency and productivity.

- Risk minimisation: GAMP5’s risk-based approach enables companies to focus resources on critical sections and minimise the risk of system failures and errors.

Conclusion

In summary, GAMP5 is an indispensable tool for pharmaceutical companies that want to maintain high quality and compliance standards in their automated systems. By adhering to its principles and guidelines, companies can improve their operations, reduce risks and ultimately deliver safer and more effective pharmaceutical products.

Start your digital transformation with our powerful, modular software solutions

Frequently Asked Questions (FAQs)

What is GAMP5?

GAMP5 stands for “Good Automated Manufacturing Practice 5” and is a set of guidelines for ensuring the quality and compliance of automated systems in the pharmaceutical industry.

Who developed GAMP5?

GAMP5 was developed by the International Society for Pharmaceutical Engineering (ISPE).

Why is GAMP5 important for pharmaceutical companies?

GAMP5 is important for pharmaceutical companies to ensure the reliability, compliance and quality of their automated systems and to reduce the risk of regulatory issues and product recalls.

What advantages does GAMP5 offer pharmaceutical companies?

GAMP5 benefits pharmaceutical companies by improving regulatory compliance, enhancing product quality, increasing efficiency and minimising risks in automated systems.

What factors influence the validation effort according to GAMP, and how is the scope and number of controls for a computerised system within the framework of functional risk management determined?

In practice, the validation effort according to GAMP depends on the data security parameters, the complexity and the novelty of the IT system used. This changes the way we see and work and conscious decisions have to be made. Initial basic risk evaluation is performed and then the impacts of the system are analysed. The functions that have an impact on data security, product quality and data integrity are then identified. Based on the functions, functional risk management begins and the scope and number of controls of the computerised system are defined. These must then be implemented and verified accordingly. The resulting monitoring of the entire lifecycle enables the optimisation of workflows and processes, such as the avoidance of duplicate activities through the integration of computer system activities.

What requirements and prerequisites should be considered when selecting and working with an IT supplier in a regulated environment, particularly with regard to quality assurance and compliance?

If a company in a regulated environment wishes to be strengthened by the work of an IT supplier, the approach of pre-verification of the suitability and reliability of the supplier also applies here. The IT company, in turn, must consistently implement the agreed quality assurance measures and therefore comes under greater scrutiny by the supervisory authorities. This results in a number of requirements for the supplier. In this context, GAMP5 considers quality-assured software development in accordance with a lifecycle model, the V-model, quality-assured and documented adaptation and implementation of the software and corresponding quality-assured maintenance and support to be appropriate. The aspects have to be illustrated based on a quality management system.