Definition of the term ("What is a Device Master Record?")

A Device Master Record is a technical product file with a compilation of documents and records containing all specifications and manufacturing procedures for a medical device(FDA 21 CFR 820). The term Device Master Record was coined by the US Food and Drug Administration (FDA) and is part of the Quality Assurance Regulations (QSR).

What is the connection to the FDA?

As developments in the medical device section have increased enormously in recent years, the regulatory authorities are also constantly facing new hurdles. The FDA (Food and Drug Administration) has become an international role model with its reliability and consistent regulation. With regard to the FDA, the Device Master Record represents one aspect of the comprehensive documentation system aimed at regulating the quality assurance of medical devices. While the FDA only focuses on devices for the US market, the revision of ISO 13485(: 2016) and the Medical Device File anchored in it now also make quality assurance(QA) documentation mandatory in Europe.

What are the components of a DMR?

Device specifications:

- Detailed device designs and specifications.

- Material specifications.

Component drawings and specifications. - Product label and packaging details.

Manufacturing process:

- Step-by-step assembly instructions.

- Quality control procedures.

Calibration procedure. - Test and inspection protocols.

Quality control records:

- Records of quality control tests.

- Reports on deviations and corrective measures.

- Supplier audits (the quality management representative of a customer audits his supplier) and proofs.

Records of the device history:

- Production records for each batch.

- Records for device distribution.

- Complaints and returns documentation.

Records of labeling and packaging:

- Labeling design and content.

- Packaging specifications.

- Instructions for use and safety information.

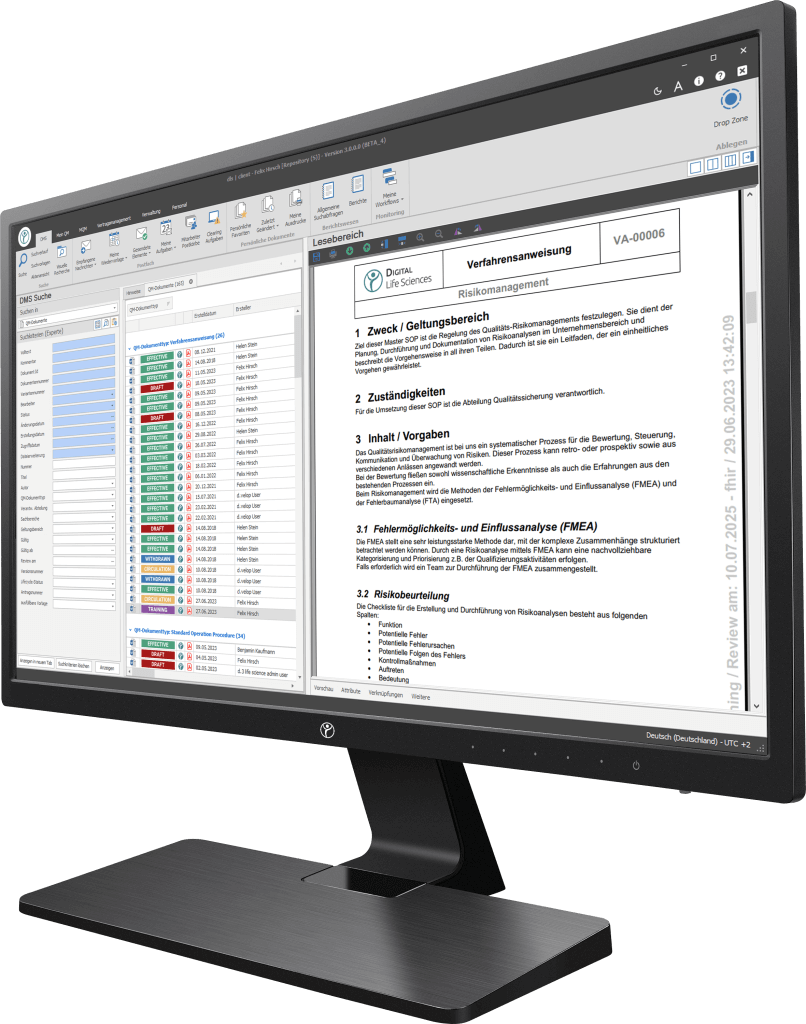

Your path to digitisation - Discover our software

Our digitisation solutions primarily address document-based processes in manufacturing, production and quality management. The basis of the dls | eQMS is a holistic ECM/DMS system. The ECM/DMS system can be connected to your existing ERP system (e.g. SAP) and thus map almost all document-based processes in the company.

Why is a Device Master Record (DMR) important?

- Ensuring consistency: A well-maintained DMR is crucial to ensure that every device manufactured is consistent in design, quality and performance. This consistency is crucial in order to meet customer expectations and regulatory requirements.

- Regulatory compliance: Regulatory authorities such as the FDA in the United States require medical device manufacturers to maintain a DMR. Compliance with these regulations is non-negotiable, and a robust DMR is key to meeting these requirements.

- Traceability and responsibility: In the event of product problems or recalls, a DMR enables manufacturers to trace the cause of the problem. This traceability is crucial for accountability and continuous improvement.

- Efficiency and cost reduction: Efficient manufacturing processes lead to cost savings. A well-organised DMR optimises production, reduces errors and minimises waste, which ultimately leads to cost savings.

How do I create a DMR?

Document control:

- Implement qualitative Document Control to efficiently manage DMR components.

- Ensure that all changes to the DMR are documented, reviewed and approved.

Version control:

- Maintain version control to prevent the use of outdated documents or procedures.

- Archive older versions for reference.

Collaboration in interdisciplinary teams:

- Involve cross-functional teams in the creation and maintenance of the DMR, including design, production and quality control.

Regular audits:

- Perform regular internal audits to verify the accuracy and completeness of the DMR.

- Edit deviations immediately.

Conclusion

In the medical device manufacturing section, the technical product record (DMR) is the cornerstone of quality, consistency and regulatory compliance. By meticulously documenting every aspect of device design, production and quality control, manufacturers can ensure the safety and effectiveness of their products.

Remember, a well-maintained DMR not only pleases regulators, but also contributes to the success and reputation of your organisation. So accept the DMR as your ally in deploying world-class medical devices to the world.

Start your digital transformation with our high performance, modular software solutions

Frequently Asked Questions (FAQs)

Is a Device Master Record (DMR) mandatory for all medical devices?

Yes, a DMR is a regulatory requirement for all medical devices to ensure their quality and safety.

How often should a DMR be updated?

DMRs should be updated when there are changes to device specifications, manufacturing processes or quality control procedures.

Can a DMR be in electronic format or is a physical recording required?

DMRs can be in electronic format as long as they meet the regulatory requirements for data security and integrity.

What happens if a company fails to maintain a DMR?

Failure to maintain a DMR can result in regulatory non-conformity, product recalls and legal consequences.